Electronic rubber is an emerging material that combines the elasticity and flexibility of rubber with electrical and electronic functionality. In recent years, with the rapid advancement of technology and the increasing demand for intelligent and flexible electronics, the development of electronic rubber has gained significant momentum and is expected to continue evolving in the coming years.

Silicone, a versatile material, has become an indispensable part of our daily lives due to its unique properties and advantages. In this article, we'll explore the various applications of silicone products in our day-to-day existence.

The petrochemical industry plays a crucial role in the global economy, and rubber products have become an indispensable part within this sector. Rubber, with its unique properties and versatility, has found extensive applications in various aspects of the petrochemical industry.

With the rapid development of China's manufacturing industry, the application of rubber products has become more and more extensive, which rubber products can be seen everywhere, do you know how they are made?

In general, there are two common forming methods for rubber products: molding and extrusion, which can be made into sealing rings, rubber strips, rubber hoses, rubber sleeves, gaskets and so on. The function of the product is different, the size of the product is different, then the selection of the process is also different.

In today's rapidly evolving technological landscape, artificial intelligence (AI) is emerging as a powerful force that is transforming various industries, and the field of rubber materials is no exception. The integration of AI is bringing about significant changes and driving the progress of rubber materials in several ways.

Rubber products are widely used in various industries, but they may also have some common defects. Here are some of the common ones:

Marine biodiversity is of great significance for the stability and health of our entire ecosystem. In the field of marine biological protection, rubber products have played an important role. Rubber products have diverse and valuable applications in marine biological protection. They help maintain the safety and integrity of the marine environment while facilitating our efforts to protect and conserve the precious marine life within. Through proper utilization and continuous innovation, we can continue to leverage the benefits of rubber in safeguarding our oceans and the creatures that call them home.

In the world of pets, rubber products play an increasingly important role. These versatile materials have found various applications that enhance the lives of our furry friends.

Silicone products have a wide range of applications in various fields due to their unique properties.Here are some of the main areas where silicone products are commonly used:the medical field,the electronics industry,the automotive industry,household goods,construction industry,the beauty and personal care industry,food industry,the aerospace industry

Rubber products play a crucial role in the field of fluid equipment, offering a wide range of benefits and applications.

In fluid handling systems, rubber seals and gaskets are essential components. Their flexibility and sealing properties ensure that there are no leaks in pipes, valves, and pumps, preventing the escape of fluids and maintaining the integrity of the system. Different types of rubber materials are selected based on the properties of the fluid being handled, such as resistance to chemicals, temperature, and pressure.

"Compression molding technology is ideal for the production of small to large rubber parts for different applications. It enables manufacturers to use the properties of rubber to create functional products."Among the different methods of manufacturing elastic rubber parts, compression molding is a popular method. This molding method can make various rubber materials formed according to the geometry of the designed mold. Rubber compression molding produces components with high elasticity, high strength and sealing properties for a variety of industries from automotive to consumer goods.

This artical will discuss its process, advantages, industrial applications, molding precautions and so on. In the end, you will be able to decide whether it can meet your requirements or not.

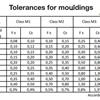

Fixed and sealed mold sizes:

F is a fixed size tolerance code, which is suitable for the size of the injection mold product and the size of the molding die is not affected by the thickness of the water outlet.

C is the size tolerance code of the sealing die, which is suitable for the size of the molding die affected by the thickness of the water outlet.

For an explanation of F and C, see the figure below

Rubber seals play a vital role in modern industry, they are widely used in a variety of machinery and equipment to ensure the tightness of fluids (liquid or gas), prevent leaks, and protect machinery and equipment from the outside environment.

Rubber compound is an excellent material for rubber products, and its product quality has a decisive effect on its vulcanized rubber and the physical and mechanical properties of the product. Therefore, the inspection of the quality of rubber is an important link in the production, and what are the methods of inspection?

Now, what type of rubber material is compatible with compression molding? The basic requirement is that rubber properties should support the flow of rubber in the mold during processing.

It is the manufacturing process of rubber parts and products that involves molding rubber materials by placing rubber into a heated mold and compressing it. At the same time, the mold contains two halves that can be opened to place the rubber and compressed to ensure the flow inside the mold. Both halves of the die (top and bottom) are connected to a compression mechanism (hydraulic, mechanical or any other type).