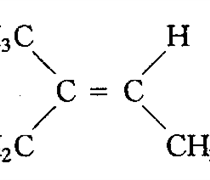

Isoprene rubber (IR), also known as synthetic natural rubber, has a series of unique characteristics and wide application fields.

Common rubber material performances,

NBR,HNBR,FKM,VQM,NR,CR,PU,EPDM,SBR,etc

Ozone resistance, heat resistance, chemical resistance, abrasion resistance, weather resistance, oil resistance...

In the world of sports, every little advantage can make a significant difference in an athlete's performance. Rubber products, often overlooked, can play a crucial role in enhancing the abilities of athletes.

NBR nitrile butadiene rubber compound is a kind of synthetic rubber material prepared by emulsion polymerization of butadiene and acrylonitrile, which is usually produced by low temperature emulsion polymerization. This rubber compound has a series of excellent performance characteristics, making it widely used in many industrial fields.

Common certifications for rubber products include ROHS, REACH, WARS, FDA, KTW, UL, NSF, IATF 16949, ISO 9001, and ISO class 8.

Rubber flame retardant products by adding flame retardants to the rubber material, so that the rubber can slow down or prevent the speed of combustion when it is heated or encountered a fire source, and even achieve self-extinguishing in some cases. The mechanism of action of flame retardants usually includes releasing water during combustion, absorbing heat, forming a protective layer or changing the combustion path, thereby reducing the flammability of the material. Here are some common application scenarios:

Production Steps of Rubber-coated PTFE Products

The production of rubber-coated PTFE products requires a series of precise steps and techniques to ensure high-quality output. Here is an overview of the production process:

The declararion of feasibility is an assurance that the proposal of design can be produced,constructed,packed and send.

It is prohibited to store unqualified raw materials and strictly inspect raw materials before production. Batch management by entry and exit time.

Kast rubber has a sound development of mold design,processing,manufacturing systems.