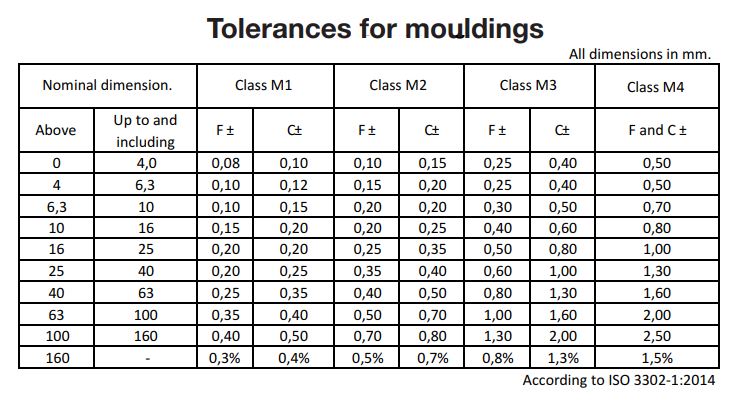

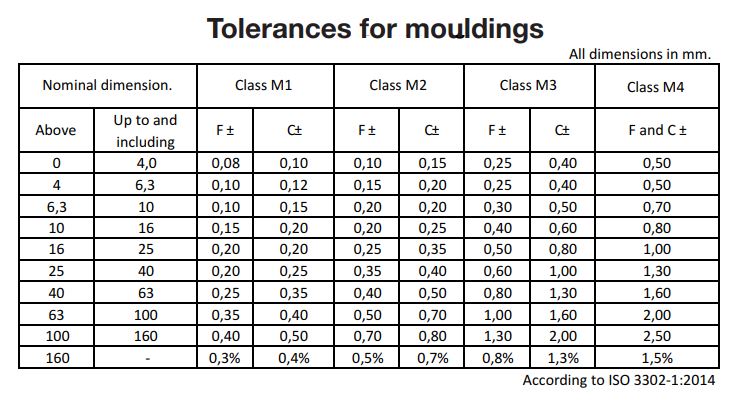

Fixed and sealed mold sizes:

F is a fixed size tolerance code, which is suitable for the size of the injection mold product and the size of the molding die is not affected by the thickness of the water outlet.

C is the size tolerance code of the sealing die, which is suitable for the size of the molding die affected by the thickness of the water outlet.

For an explanation of F and C, see the figure below

The accuracy level of dimensional tolerance of molded products is the following four levels:

M1 Precision grade: applicable to the dimensional tolerances required for precision molded products, referred to as fine grade fine molded products require the use of precision molds

The number of cavities per pair of molds should not be too much, and the weight and production process of semi-finished rubber materials should be strictly controlled. General norm

After pressure vulcanization, some kind of mechanical processing is often required. The dimensional accuracy of parts of such products requires the use of optical instruments or other

Precision measuring devices to carry out measurement, so the production cost is high.

M2 High precision level: suitable for the dimensional tolerances required for high-quality moulded products for the production of parts of such products,

The production control conditions required for the above precision grades are to be applied. High precision can be referred to as advanced.

M3 precision level: suitable for general quality molded products required by the tolerance of the precision level referred to as intermediate.

M4 Low precision level: The low precision level of unnoted tolerances for moulded products with less stringent dimensional control requirements is referred to as low.